mold-division

Mold business department

Caps for wet tissues / various plastic products / injection and mold customization and production specialized, ONE-STOP SOLUTION

Manufacturing process

The root of manufacturing : mold (product design, mold design, mold manufacturing, and injection molding)

Requirements analysis and consultation

Phase of analyzing the customers’ requirements

Maximization of the customers’ requirements by referring to similar cases and modified cases, and absent a modeling or design, a design expert from Han Ju will directly provide consulting services

Maximization of the customers’ requirements by referring to similar cases and modified cases, and absent a modeling or design, a design expert from Han Ju will directly provide consulting services

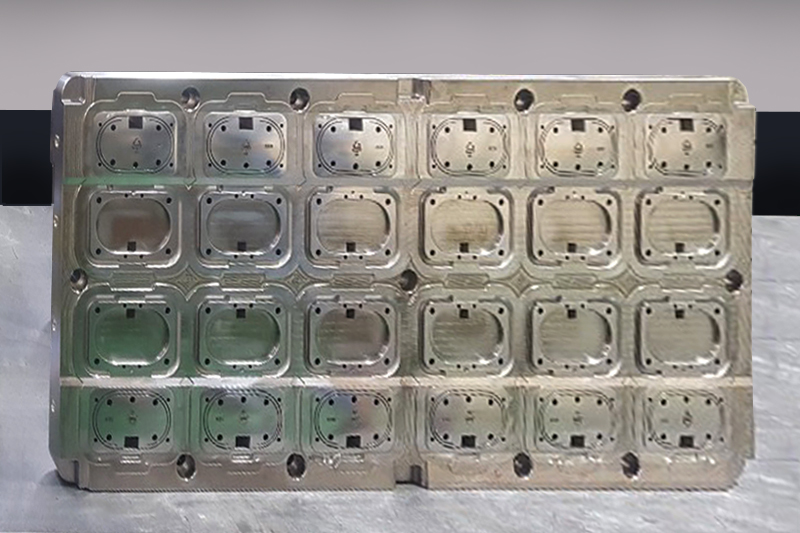

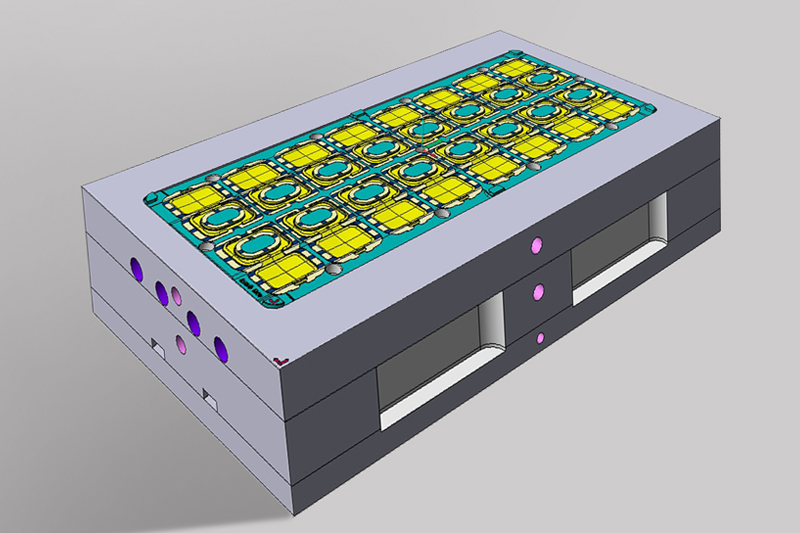

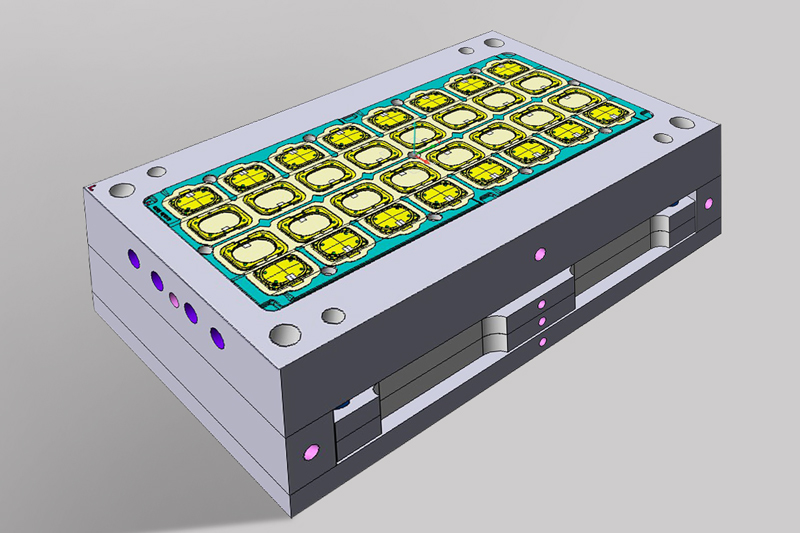

Modeling and design

Phase of reviewing the expected process and formability

The 3D-shaping of the initial product, identification of the characteristics of the manufactured product, review of the mold shape division method, and the review of manufacturing procedure, and work on the mold shaping

The 3D-shaping of the initial product, identification of the characteristics of the manufactured product, review of the mold shape division method, and the review of manufacturing procedure, and work on the mold shaping

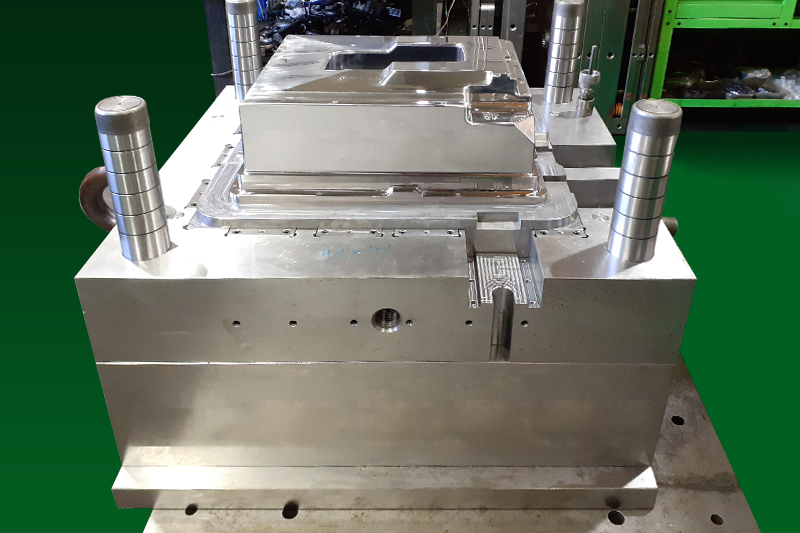

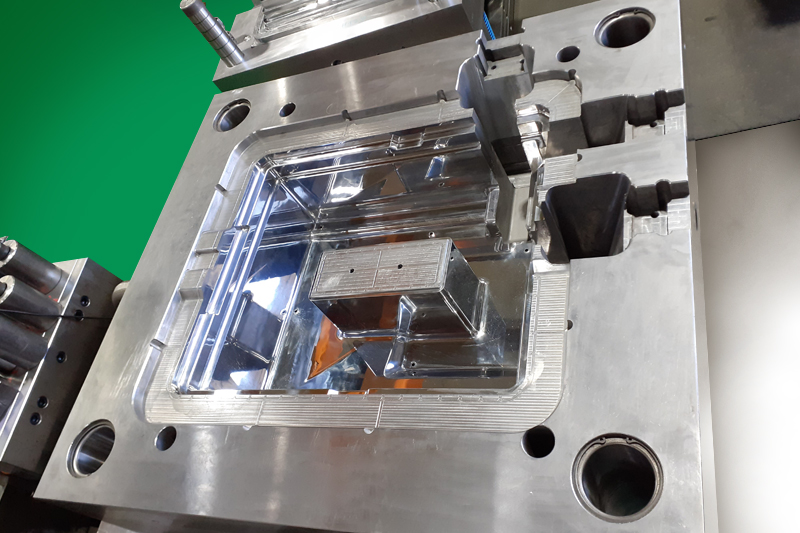

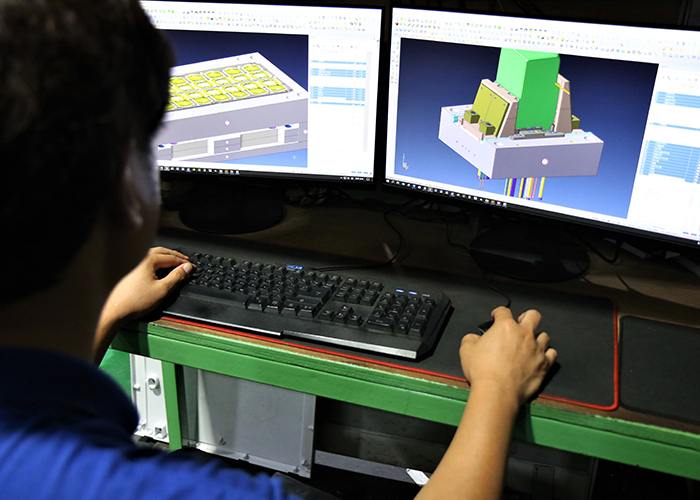

Shape processing (NC, electrical discharge, grinding, lathe, etc.)

Phase of mold base and modeling product shape processing계

NC processing, electric discharge processing, milling processing, etc. by utilizing Han Ju’s latest equipment in line with the design drawing

NC processing, electric discharge processing, milling processing, etc. by utilizing Han Ju’s latest equipment in line with the design drawing